Customizing Packaging Cartons: A Step-by-Step Guide

Customizing packaging cartons is an essential aspect of branding for businesses. It involves tailoring the design, size, and shape of the cartons to meet specific requirements. The process of customizing packaging cartons can be challenging, but it is worth the effort as it can help businesses stand out from their competitors.

The first step in customizing packaging cartons is to determine the design and size that will suit the product. This involves considering the product’s dimensions, weight, and fragility. Once the design and size are determined, the next step is to choose the material for the carton. There are various materials to choose from, including cardboard, corrugated cardboard, and plastic. Each material has its advantages and disadvantages, and the choice will depend on the product’s requirements.

Understanding Packaging Cartons

Packaging cartons are containers made of paperboard or corrugated fiberboard used for shipping, storing, and transporting goods. They come in various sizes and shapes, ranging from small boxes to large containers. Understanding the different types of packaging cartons is essential for customizing them according to your needs.

Types of Packaging Cartons

There are two main types of packaging cartons: paperboard cartons and corrugated cartons. Paperboard cartons are made of a single layer of paperboard and are commonly used for lightweight products such as cereal boxes, shoe boxes, gift boxes, and tissue boxes. Corrugated cartons, on the other hand, are made of three layers of paperboard: an inner layer, an outer layer, and a corrugated layer in between. They are more durable and are commonly used for shipping heavier items such as appliances, furniture, and electronics.

Carton Flutes

The corrugated layer of a carton is called a flute. Flutes come in different sizes, which affect the strength and durability of the carton. The most common flute sizes are A, B, C, E, and F. A-flute is the largest and thickest, providing the most strength and cushioning. F-flute is the thinnest and most flexible, providing less cushioning but taking up less space.

Carton Styles

Packaging cartons also come in different styles, which affect their shape and how they open and close. Some common styles include:

- Regular Slotted Container (RSC): The most common style of corrugated carton, with flaps that meet at the center and can be sealed with tape or glue.

- Full Overlap Container (FOL): Similar to RSC, but with flaps that fully overlap, providing extra strength and protection.

- Half-Slotted Container (HSC): Similar to RSC, but with one set of flaps missing, allowing for easier access to the contents.

- Five-Panel Folder (FPF): A flat corrugated sheet with flaps that fold up on the sides, providing extra protection for long or narrow items.

Understanding the different types of packaging cartons and their features is crucial for customizing them to your specific needs. By choosing the right carton type, flute size, and style, you can ensure that your products are shipped and stored safely and securely.

Choosing the Right Type of Carton

When it comes to customizing packaging cartons, choosing the right type of carton is crucial. The right carton will ensure that the product is protected during shipping and will also help to create a positive customer experience. There are several factors to consider when choosing the right type of carton for your product.

Firstly, consider the weight and size of the product. If the product is heavy, it is important to choose a carton that is sturdy enough to support the weight. Similarly, if the product is large, a larger carton will be necessary to accommodate the size of the product.

Secondly, consider the fragility of the product. If the product is fragile, it is important to choose a carton that provides adequate protection during shipping. This may include using additional packaging materials such as bubble wrap or foam.

Thirdly, consider the environmental impact of the carton. Choosing a carton that is made from sustainable materials can help to reduce the impact on the environment.

Finally, consider the branding and marketing of the product. Choosing a carton that can be customized with the company logo or other branding elements can help to create a positive customer experience and increase brand recognition.

In conclusion, choosing the right type of carton is an important part of the customization process. By considering factors such as weight, fragility, environmental impact, and branding, companies can ensure that their products are protected during shipping and create a positive customer experience.

Identifying Customization Needs

Customizing packaging cartons is essential for businesses that want to stand out and make a lasting impression on their customers. However, before embarking on the customization process, it is important to identify the specific needs that the packaging cartons must meet. This section will explore the different factors that businesses should consider when identifying their customization needs.

Brand Identity

One of the most important factors to consider when customizing packaging cartons is the brand identity. The packaging should reflect the brand’s values, mission, and vision. The packaging should also be consistent with the brand’s other marketing materials, such as the logo, website, and social media profiles. This will help to reinforce the brand’s identity and make it more recognizable to customers.

Product Specifications

Another important factor to consider when customizing packaging cartons is the product specifications. The packaging should be designed to protect the product during shipping and storage. It should also be easy to open and close, and should be able to withstand the rigors of transportation. In addition, the packaging should be the right size and shape for the product, and should be able to accommodate any special features or accessories.

Customer Preferences

Finally, businesses should consider the preferences of their customers when customizing packaging cartons. Customers may have specific preferences when it comes to the design, color, and material of the packaging. By taking into account these preferences, businesses can create packaging that is more appealing and engaging to their customers. This can help to enhance the overall customer experience and increase brand loyalty.

In conclusion, identifying customization needs is an important first step in the process of customizing packaging cartons. By considering factors such as brand identity, product specifications, and customer preferences, businesses can create packaging that is both functional and aesthetically pleasing.

Designing the Carton

When it comes to designing custom packaging cartons, there are two main aspects to consider: visual elements and functional design. Both are equally important in creating a carton that not only looks great but also serves its purpose.

Visual Elements

The visual design of a carton is what catches the eye of the customer and helps to create a memorable brand image. Here are a few key things to keep in mind when designing the visual elements of a carton:

- Branding: Incorporate the brand logo, colors, and other branding elements into the design to create a cohesive look.

- Graphics: Use high-quality graphics and images that are relevant to the product being packaged.

- Typography: Choose a font that is easy to read and fits with the overall design aesthetic.

- White Space: Leave enough white space to create a clean and uncluttered look.

Functional Design

The functional design of a carton is just as important as the visual design. The carton must be able to protect the product during shipping and handling, as well as be easy to open and close. Here are a few key things to keep in mind when designing the functional elements of a carton:

- Material: Choose a material that is strong enough to protect the product, but also lightweight to keep shipping costs down.

- Size: Ensure that the carton is the right size for the product being packaged to prevent damage during shipping.

- Flaps: Design the flaps to be easy to open and close while still providing a secure closure.

- Inserts: Consider adding inserts to the carton to help protect the product and keep it in place during shipping.

By considering both the visual and functional design of a carton, businesses can create custom packaging that not only looks great but also serves its purpose.

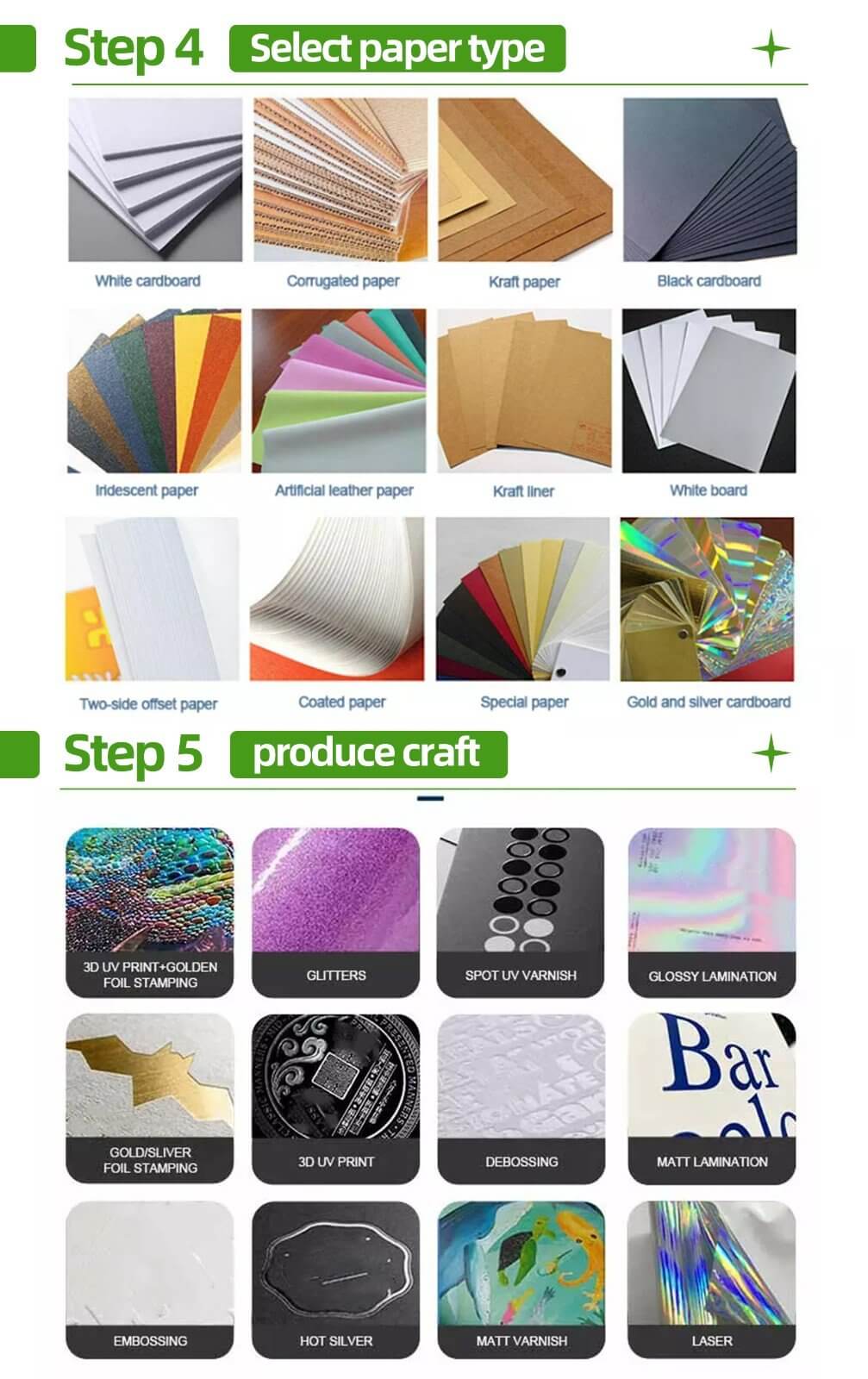

Selecting Materials

Carton Material

When customizing packaging cartons, selecting the right carton material is crucial. The chosen material should be sturdy enough to protect the product during transportation but also lightweight to reduce shipping costs.

There are various types of carton materials available, and each has its advantages and disadvantages. Here are some of the most commonly used carton materials:

- Corrugated: This is the most popular carton material and is made of three layers of paper. It is lightweight, durable, and recyclable.

- Solid Fiberboard: This material is made of a single layer of paper and is ideal for lightweight products. It is not as durable as corrugated but is still a cost-effective option.

- Folding Cartons: These are made of paperboard and are commonly used for retail packaging. They are lightweight and can be printed with high-quality graphics.

When selecting carton material, it is essential to consider the product’s weight, size, and fragility. It is also important to ensure that the material is sustainable and environmentally friendly.

Printing Material

After selecting the carton material, the next step is to choose the printing material. The printing material should be of high quality to ensure that the graphics and text on the carton are clear and legible.

Here are some of the commonly used printing materials:

- Flexography: This is a high-speed printing process that uses flexible printing plates. It is ideal for printing large quantities of cartons quickly.

- Lithography: This printing process uses a flat plate to transfer the image onto the carton. It produces high-quality graphics and is ideal for printing small quantities of cartons.

- Digital Printing: This is a newer printing technology that uses digital files to print the cartons. It is ideal for printing small quantities of cartons with high-quality graphics.

When selecting the printing material, it is essential to consider the quality of the graphics and text, the quantity of cartons needed, and the budget.

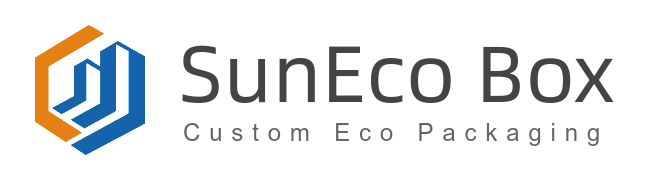

Printing Process

Once the design for the packaging carton has been finalized, the next step is to print it onto the carton. This process involves several steps and requires the use of specialized equipment.

The first step in the printing process is to create printing plates. These plates are made from a high-quality aluminum material and are used to transfer the design onto the carton. The plates are created using a computer-aided design (CAD) program that allows for precise and accurate printing.

Once the plates have been created, they are loaded onto the printing press. The printing press is a large machine that is capable of printing thousands of cartons per hour. The cartons are fed into the machine and the printing plates transfer the design onto the carton.

In order to ensure that the design is printed correctly, the printing press is equipped with several sensors and cameras. These devices monitor the printing process and make adjustments as necessary to ensure that the design is printed accurately.

After the cartons have been printed, they are inspected for quality control. Any cartons with defects or errors are removed from the production line and replaced with new ones.

Overall, the printing process is a crucial step in the customization of packaging cartons. With the use of specialized equipment and careful attention to detail, manufacturers can ensure that each carton is printed accurately and meets the highest quality standards.

Quality Assurance

Quality assurance is an essential step in the packaging customization process. It ensures that the packaging cartons meet the required specifications and are of high quality. The following are the quality assurance steps that manufacturers take to ensure that the packaging cartons are of high quality:

- Inspection of Raw Materials: The first step in quality assurance is the inspection of raw materials. The manufacturer inspects the materials to ensure that they meet the required standards and are of high quality.

- Quality Control during Production: The manufacturer ensures that quality control measures are in place during the production process. This includes regular inspections of the packaging cartons to ensure that they meet the required specifications.

- Testing: The manufacturer conducts tests on the packaging cartons to ensure that they meet the required standards. This includes tests for strength, durability, and resistance to moisture and other environmental factors.

- Packaging and Shipping: The manufacturer ensures that the packaging cartons are properly packaged and shipped to the customer. This includes ensuring that the packaging is secure and that the cartons are not damaged during shipping.

In conclusion, quality assurance is an essential step in the packaging customization process. It ensures that the packaging cartons meet the required specifications and are of high quality. Manufacturers take various steps to ensure that the packaging cartons are of high quality, including inspecting raw materials, quality control during production, testing, and proper packaging and shipping.

Logistics and Delivery

Once the customization process is complete, the packaging cartons are ready to be shipped to their final destination. The logistics and delivery phase is a critical component of the entire process, ensuring that the customized cartons arrive at their intended location on time and in good condition.

To ensure efficient and timely delivery, it is essential to work with a reliable logistics partner. This partner should have experience in handling fragile items, as well as a proven track record of delivering goods on time. Additionally, the logistics partner should have a robust tracking system in place, allowing customers to track their shipments in real-time.

When it comes to delivery, there are several factors to consider, including the size and weight of the cartons, the distance they need to travel, and any special handling requirements. It is essential to work with the logistics partner to determine the best mode of transportation, whether it be by air, sea, or land.

Once the cartons are en route, it is crucial to monitor their progress closely. This includes tracking their location, ensuring that they are being handled properly, and addressing any issues that may arise during transit. By staying on top of the logistics and delivery process, customers can rest assured that their customized packaging cartons will arrive at their destination on time and in good condition.

The detailed process for customizing packaging cartons

Communication stage

① What type of packaging box do you need? What type of box is it for cosmetics, health products, or gifts? What material is used? What kind of effect is needed?

② What is the printing quantity? How long is the delivery cycle? What is the price?

③ Information and communication plan between both parties.

① Product Confirmation

1. Material

Commonly used packaging box materials include white cardboard, silver cardboard, gray board, coated paper, corrugated paper, etc.

2. Box type

Front and back buckles (same direction buckles), self-locking bottom, bottom insertion and side bonding, heaven and earth cover boxes, irregular boxes, etc.

shipping box, gift box, fruit box ect.

3. Printing process

Reverse glazing, embossing, gold stamping, silver stamping, film covering, etc

Printing, design price, process requirements

Determine the final price based on material, quantity, printing, design, and other requirements.

Production cycle

Confirm the design cycle (usually 1-3 days) and delivery cycle (usually 7-15 days).

Packaging box design

Provide reference boxes, graphic materials, process requirements, etc. to manufacturers, create documents, and communicate relevant details.

Packaging box sampling

After the sample is made, the manufacturer confirms that the sample meets its own requirements. If it does not meet the requirements, corresponding modification suggestions are proposed to determine the final plan.

Confirm the order.

After confirming that the sample (packaging box) is correct, place an order to start customized production of the packaging box.

Sign a contract

Confirm the style, material, size, design, production cycle, etc. of the product, and sign a cooperation agreement.

By Sofier

By Sofier